APPLICATIONS

Into the next level of sustainable cosmetic packaging

A CRITICAL ANALYSIS OVER EXISTING SOLUTIONS AND AN APPROACH FOR SUSTAINABALE COSMETIC PACKAGING USING WOOD-BASED CLOSURE APPLICATIONS

10 min | © rezemo GmbH

INTRO

At a gaze into their bathrooms, consumers quickly notice that there is a large amount of plastic being used in cosmetics packaging. This clearly shows the extent and importance of cosmetics packaging for today’s industry. Cosmetics manufacturers are facing a major challenge. Cosmetic packaging should protect the product, look beautiful and be sustainable at the same time.

Does the existing approach ‘reduce’, ‘reuse’, ‘recycle’ provide a comprehensive solution for the packaging dilemma? Following I describe how we understand and design products to fit a circular packaging economy.

1

The sobering numbers behind single-use cosmetics packaging

With sales of €77 billion, Europe is the world’s largest market for cosmetic products. More than half of these sales come from Europes two largest economies – Germany and France. According to estimates by the American market research institute Transparency Market Research (2016), the global market for cosmetics packaging will grow by 4.4 percent annually until 2024.

In cosmetics, the packaging is an essential component of the product. Cosmetic packaging is demanding, because of hygienic claims, frequently changing product lines, and differentiation reasons.

Manufacturers therefore often rely on single-use packaging.

However, it is precisely this single-use packaging that accounts for most of our waste. According to The Independent, we dispose 142 billion pieces of cosmetics packaging worldwide every year. We cannot longer ignore this figure concerning the debates about environmental pollution, waste exports, or animal deaths. Without a fundamental change in packaging strategy, a growing cosmetics market will inevitably lead an increasing disposal problem.

we dispose 142 Billion pieces of cosmetics packaging worldwide every year

© rezemo GmbH

2

An industry calling for more sustainability: the pull factors

Natural cosmetics, often also referred to as ‘Clean Beauty’, ‘G-Beauty’ or ‘Green Cosmetics’ have been an integral part of the cosmetics industry for years. However, the market share continues to grow vastly – by a complete 9% in Germany in 2019. Behind this is the desire of consumers for more nature and less chemistry on their skin. Those who buy natural cosmetics not only want to avoid harmful ingredients and do something good for themselves, but also want to contribute to a more sustainable future. As consumers become more conscious in choosing their cosmetic products, brands are increasingly striving to design their products to be fairer, more vegan, more resource-efficient, and more natural. But a holistic sustainability system should not end with the packaging.

According to a recent survey of GfK consumer panels in 2020, consumers demand more sustainable packaging in cosmetics and see packaging as the lowest common denominator for the cosmetics industry to start driving sustainability.

Besides, public awareness of plastic waste escaping into the environment has risen to a maximum in recent years. Dramatic images of plastic pollution around the world, especially the trash-laden oceans, have made consumers more aware of the disposal issue.

Therefore, it is understandable that consumers are paying more and more attention to the packaging they use and are adding more sustainable alternatives to their shopping list. Another study by the STI Group (2015) shows that well-known seals such as FSC for outer packaging and the German Green Dot are becoming increasingly important for consumers and that they are also willing to spend more money on sustainable alternatives. Moreover a McKinsey study from back in 2012 highlights that sustainable packaging is the top criterion for which consumers are willing to pay more.

See McKinsey 2012

sustainable packaging is the top criterion for which consumers are willing to pay more

3

HOW PUBLIC REGULATIONS COMPLETE THE TREND: the push factors

On the other hand, authorities are actively addressing the issue of packaging waste. They are pushing fast-moving consumer goods (FMCG) manufacturers and retailers, including food and cosmetics manufacturers, to fundamentally rethink their packaging concepts through new regulations.

Many nations are tightening their packaging guidelines and developing an agenda for a plastic-free future in the FMCG sector, as the following analysis by McKinsey (2020) shows.

See McKinsey 2020

Packaging manufacturers will be held increasingly accountable for disposal and that particular DECICIONS ON sustainable packaging will receive economic subsidies

For example, the EU has enacted a ban on single-use plastic items such as straws, cotton swabs, and disposable cutlery, which will come into force in mid-2021. Back in 2015, the EU Commission presented draft legislation to ensure that all plastic packaging placed on the EU market by 2030 is either reusable or recyclable. Besides, the law stipulates that packaging manufacturers will be held increasingly accountable for disposal and that particular decisions on sustainable packaging will receive economic subsidies.

These framework conditions are increasingly motivating cosmetics manufacturers to overthink their packaging concept. On the one hand, to meet the growing sustainability needs of consumers on the market. This secures valuable market shares in the growing market for sustainable cosmetics. On the other hand, to comply with legal regulations for plastic and waste prevention. Summing up these developments, it becomes clear that cosmetics manufacturers should be as sustainable as possible as soon as possible.

4

three approaches for more sustainable cosmetics packaging

There are basically three approaches available to environmentally conscious packaging developers for an ecological solution:

- Reuse

The idea of designing cosmetic packaging in a way that it can be reused after its initial use is certainly one that has the smallest impact on the environment. Individual cosmetics manufacturers are adopting this concept with the help of special refill stations in drugstores or individual return systems. In practice, however, these approaches have not made it beyond small-scale trials. The necessary change in the value chain of cosmetic manufacturers is expensive & hygienically problematic. Cleaning the containers is energy-intensive and thus also associated with high costs. Besides, packaging essentially also has an aesthetic, sales-promoting function. It should encourage the customer to buy through a combination of extravagant design and customer-relevant information, something that current refill systems to a great extent are unable to achieve.

- Recycle

The most common concept in practice is recycling. In theory, all packaging materials such as glass, plastic, cardboard, etc. are recyclable. But recyclable does not automatically mean that e.g. plastic packaging will become plastic packaging again. The problem here is that most of today’s packaging solutions cannot be separated by type in the existing recycling systems.

Composite packaging, which consists of several different materials, cannot be separated by type and is therefore unsuitable for recycling.

In the past, however, recycling was not in focus for most packaging manufacturers in the cosmetics industry. Bottles and jars should first and foremost look good, stand out and encourage people to buy them. In Europe, the reported recycling rate for plastic packaging is therefore at just 14%. Even of these, the majority are recycled into so-called lower-value applications like shopping bags, condiment sachets, or confectionary wrappers. These are products that are nearly unable to recycle again after use, mostly because they tend to be mixed plastics, combined with other layers of materials such as foil or soiled by food waste.

The actual result is sobering: According to Ellen MacArthur Foundation (2016), only 2% of recycled packaging finds its way into new plastic packaging. Instead, 98% of plastics used for the annual plastic production comes from a virgin feedstock, i.e. fresh crude oil, which is not available in unlimited quantities on our planet. Most of the plastic packaging instead ends up in landfills (40%), incinerators (14%), or pollutes our environment (32%), meaning these materials are lost forever despite their cost-intensive manufacturing. The figures refer to plastic packaging in general but can be transferred to cosmetics packaging accordingly.

recyclable does not automaticallY mean that E.g. plastic packaging will become plastic packaging again

98% of plastics used for the anual plastic production comes from a virgin feedstock, i.e. fresh crude oil, which is not available in unlimited quantities on our planet

See Ellen MacArthur Foundation 2016

- Reduce

The third approach deals with reducing the amount of material used for packaging. The cosmetics industry is experimenting with thinner-walled plastic packaging. These are then often particularly difficult to recycle because they are not designed as mono-materials but either as composite materials or high-performance polymers. Brands are adopting the zero-waste idea and in some cases even

dispensing with packaging completely by removing the water from their lotions and selling them as solid products in pieces. But even this manner does not completely solve the problem, as even most zero-waste concepts are forced to protectively wrap their products in some form. In most cases, thin plastic films or cardboard sales packaging is used to display essential information such as ingredients or other legally required information.

5

the solution appears to be (crystal) clear

With so many factors involved in choosing the right concept, putting together a sustainable packaging is not easy. By today, there is no crystal-clear solution. Compared to fossil plastic, glass has reasserted itself in some industries, including beverages, food, and pharmaceuticals. This is because glass has many advantageous properties that also make it suitable for cosmetics:

- Glass is neutral to its contents and has good barrier properties, so it does not absorb or let in any substances

- Glass is stable, heat-resistant, and can withstand temperatures of up to 500 degrees Celsius, making it easy to clean at high washing-up temperatures

- Amber glass is almost impermeable to UV radiation and thus protects particularly light-sensitive cosmetics such as natural cosmetics since they do not contain any preservatives

- Glass is transparent and conveys transparency of content as well as high quality to the customer

But looking at its carbon footprint, glass must make concessions. On the one hand, the energy demand for glass production is high and this would have to be capped using renewable energies to make it as environmentally friendly as possible.

Secondly, the weight is higher than with plastic packaging, which leads to higher energy consumption during its transportation.

However, glass is mostly considered an environmentally friendly material. Thanks to the properties just mentioned, it can be easily rinsed out and thus theoretically be refilled indefinitely (reuse), in practice up to 50 times as demonstrated by the beverage industry, which puts its initially higher energy demand into perspective.

And even when the refill cycle comes to an end and the packaging is recycled, glass packaging occupies one of the top positions in recycling compared to other materials. According to German Federal Environmental Agency (2020), the recycling rate for glass packaging in Germany has been on an average of 85.5% in recent years. A study by the Cyclos-HTP Institute (2019) even speaks of a recycling rate of up to 99% if the glass can be separated from its closure material.

Packaging a cosmetic product in glass therefore not only seems to make sense but in practice, it is also the most obvious option for many cosmetics manufacturers who have committed themselves already to sustainability. However, there is still one problem to be solved: How can glass packaging be closed sustainably?

6

Closing the loop trough wood biopolymer closures

Here it is worth taking a different view on the topic and shifting the focus from the disposal side to the ingredients side. What if it is no longer relevant where packaging ends up, but what it is made of?

If only natural raw materials are used to manufacture a product package, then, simply put, only natural things remain. No fossil raw materials, no microplastics, and therefore no disposal problem. What if raw materials could be used, that are locally sourced in sufficient quantities as a waste product and are completely renewable? – Such as wood chips that are left over from the wood processing industry.

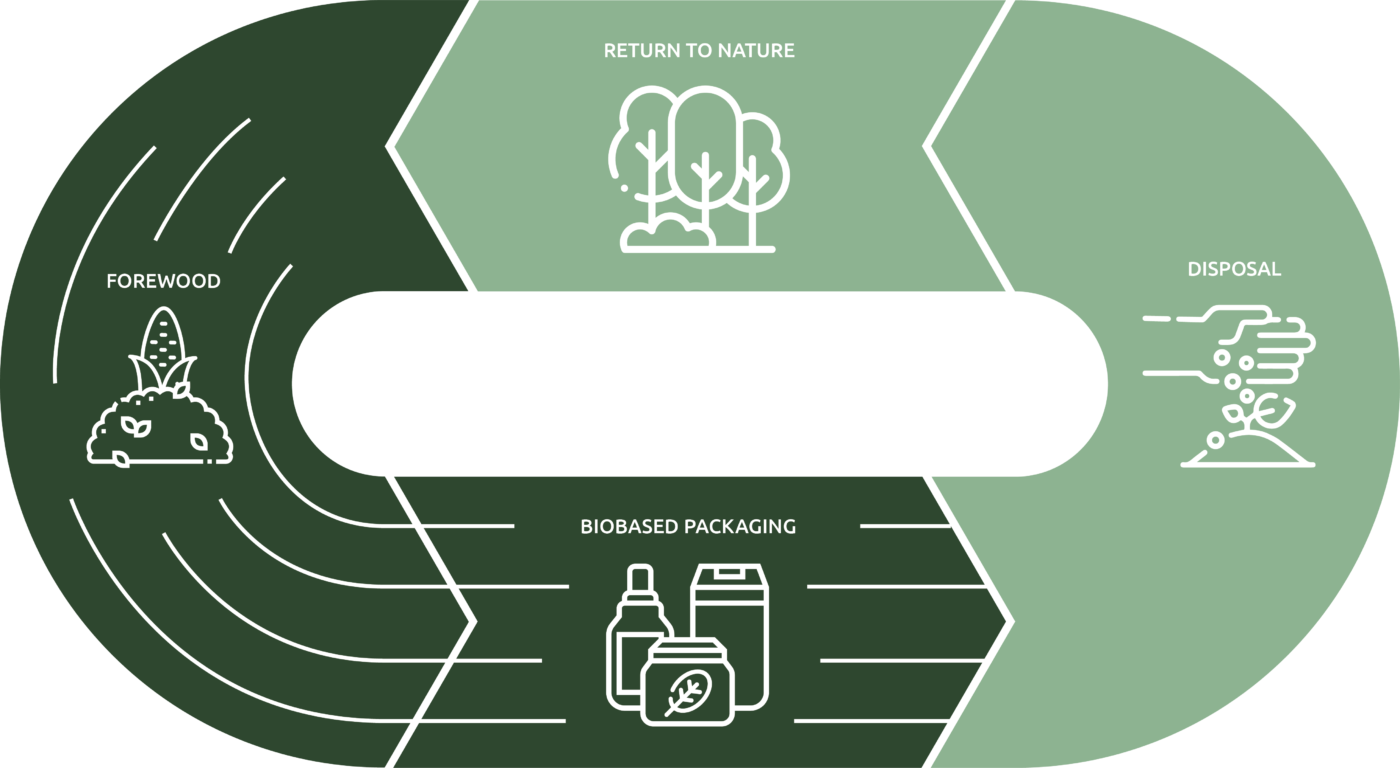

We, forewood, are a young and highly innovative company that has made use of these raw materials to produce sustainable closure applications. In years of research with renowned research institutes, we have developed an innovative technology of processing sustainable materials by embedding wood fibers in a polymer matrix fully made of biopolymers. The processing of this material in an injection molding process enables us to produce complex thin-walled closure applications for cosmetics packaging that are tailored to the individual needs of the customer. More detailed information about the forewood technology can be found here.

© rezemo GmbH

if only natural raw materials are used to manufacture a product package, then, simply put, only natural things remain

As a specialist in the field of wood fiber biopolymer compounds, we successfully placed first product applications on the market. The use of renewable raw materials, therefore, solves the packaging dilemma.

It follows the cradle-to-cradle principle, which gives packaging a whole new dimension. The products can be returned to nature after use – minimizing its environmental impact and ready to close the cycle and eventually grow into the next plant.

the products can be returned to nature after use – minimizing its environmental impact and ready to close the cycle

© rezemo GmbH

A wood-based closure application thereby is not only sustainable, but its sustainability is also visible and tangible. In doing so, it hits the customers’ nerve for sustainability in their bathrooms, because the customer doesn’t only choose a beauty product, but the philosophy and mission behind it. Cosmetics manufacturers face the challenge of communicating

a holistic sustainable image to their customers in a tangible way, which is first and foremost reflected in the packaging. Where other bioplastics fail, forewood lets consumers see and feel naturalness and manages to communicate the philosophy of a sustainable brand to customers in a sustainable way. And who better to do that than forewood?

A Wood-based closure application thereby is not only sustainable, but its sustainability is also visible and tangible

BE A PIONEER IN SUSTAINABLE COSMETICS PACKAGING

AND MEET THE NEEDS OF YOUR CUSTOMERS WITH THE HELP OF YOUR INDIVIDUAL FOREWOOD APPLICATION.

© rezemo GmbH